The Dock Platform Stertil Dock Products

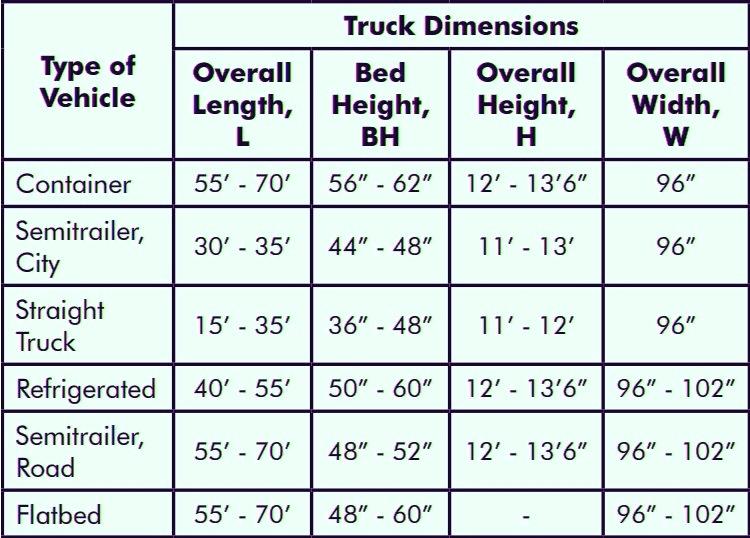

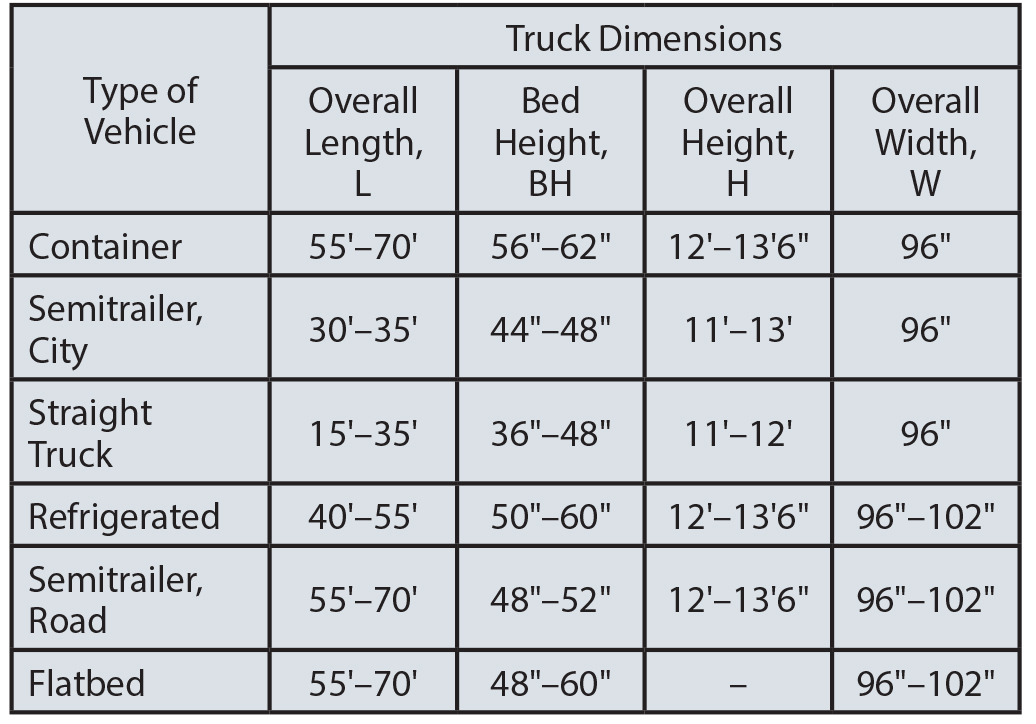

Dimensions of the loading docks and doors Characteristics of the facility processes Then, consider the dock height, loading bay width, and dimensions and layout of the building interior. TRUCK SPECIFICATIONS Determine the types and dimensions of the trucks that will use the docks. List each truck's length, width, height and bed height.

How to Measure for Loading Dock Approach (Incline/Decline) YouTube

Semi truck - 48"-52" Flat-bed truck - 47"-62" City delivery truck - 45"-48" Low-boy truck - 19"-25" Loading Dock Dimensions What is the right dock height? There is no one answer. The average loading dock height is between 48 and 52 inches. To determine the proper loading dock height, here are some questions to ask:

bedwidthsdesigntheloadingdocktruckspecificationstruckdimensionsofvehicleoverall

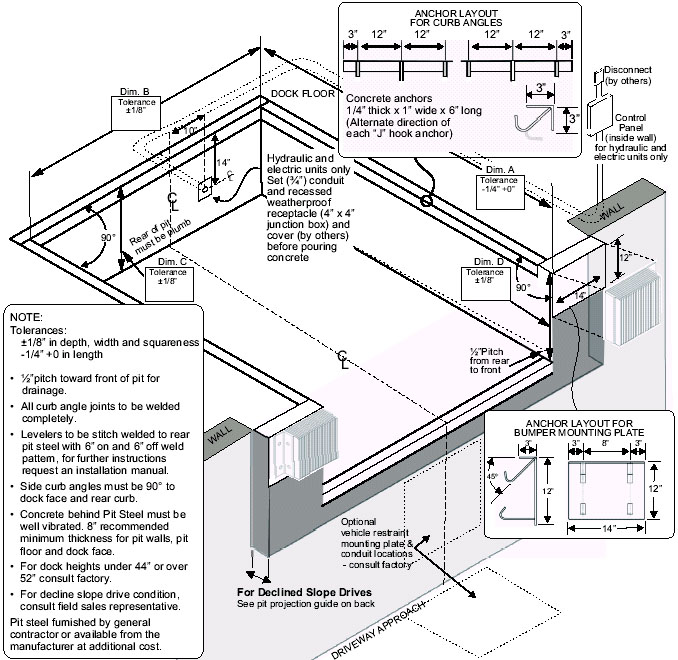

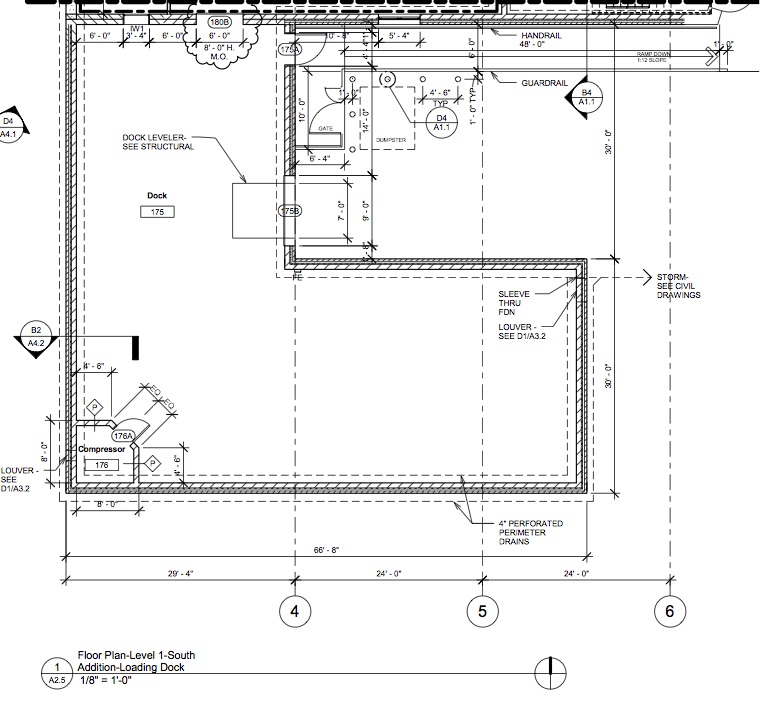

Design factors such as standard loading dock dimensions, loading dock design layout, loading dock door spacing, as well as sizing and specifying the correct type of loading dock levelers and interior and exterior doors, among other things, can set an architect or general contractor apart from others.

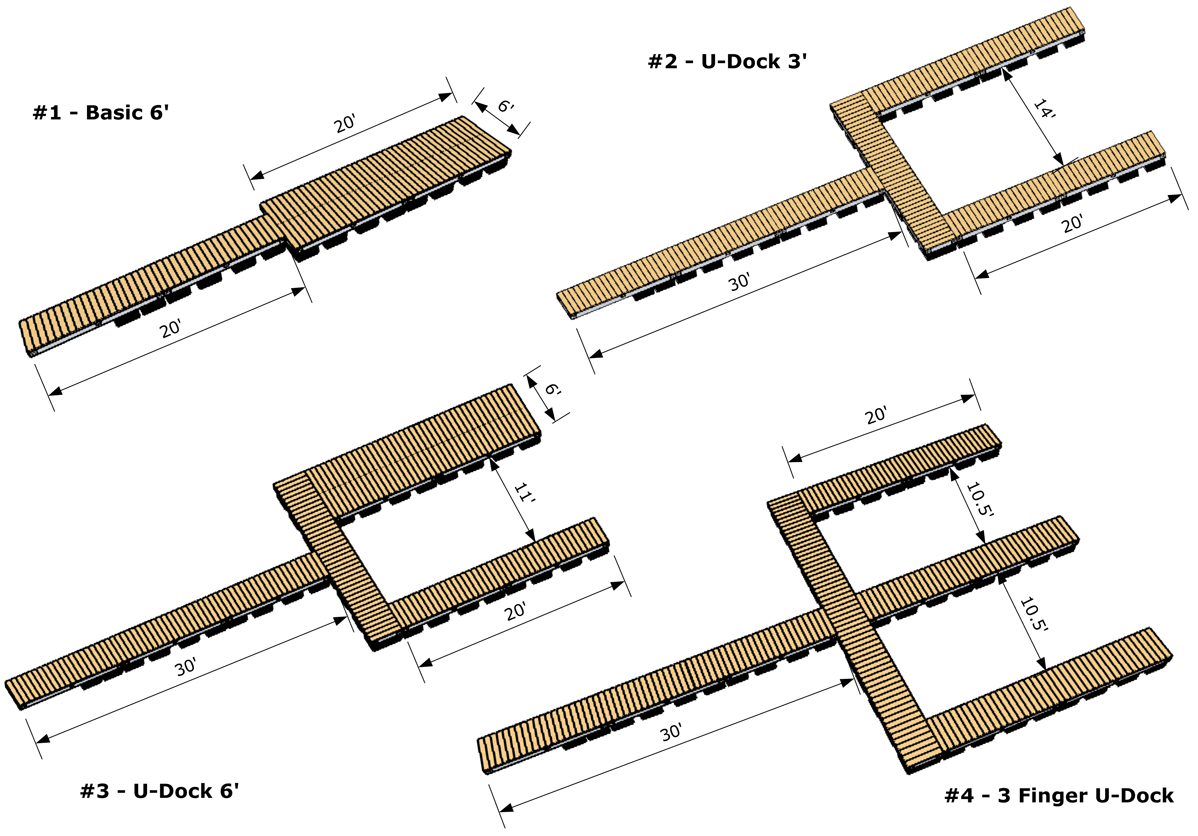

Dock Guide American Muscle Docks & Fabrication

Within North American facilities, the standard dock height is 48 in. However, dock heights typically range from 48 in. (120 cm) to 52 in. (130 cm), and heights of up to 55 in. (140 cm) are not uncommon. Facilities that employ unique trailer configurations may utilize different dock heights to accommodate their shipment containers.

Pin su Guidelines

The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in detail in Set the Dock Height on page 10). When using electric powered loading equipment, the maximum grade percentage is 10%. For gas or diesel powered loading equipment the maximum grade percentage is 15%. If these grade

Loading Dock Design Strategies for Science & Technology Facilities — Ci

The maximum grade percentage from the loading dock to the vehicle is determined by the height of the dock (discussed in detail in Set the Dock Height on page 10). When using electric powered loading equipment, the maximum grade percentage is 10%. For gas or diesel powered loading equipment the maximum grade percentage is 15%. If these grade

What is the standard loading dock height? Loading Dock Pro Parts & Aftermarket Products

¡Precios increíbles y alta calidad aquí en Temu. Envío gratuito en todos los pedidos. ¡Solo hoy, disfruta de todas las categorías hasta un 90% de descuento en tu compra.

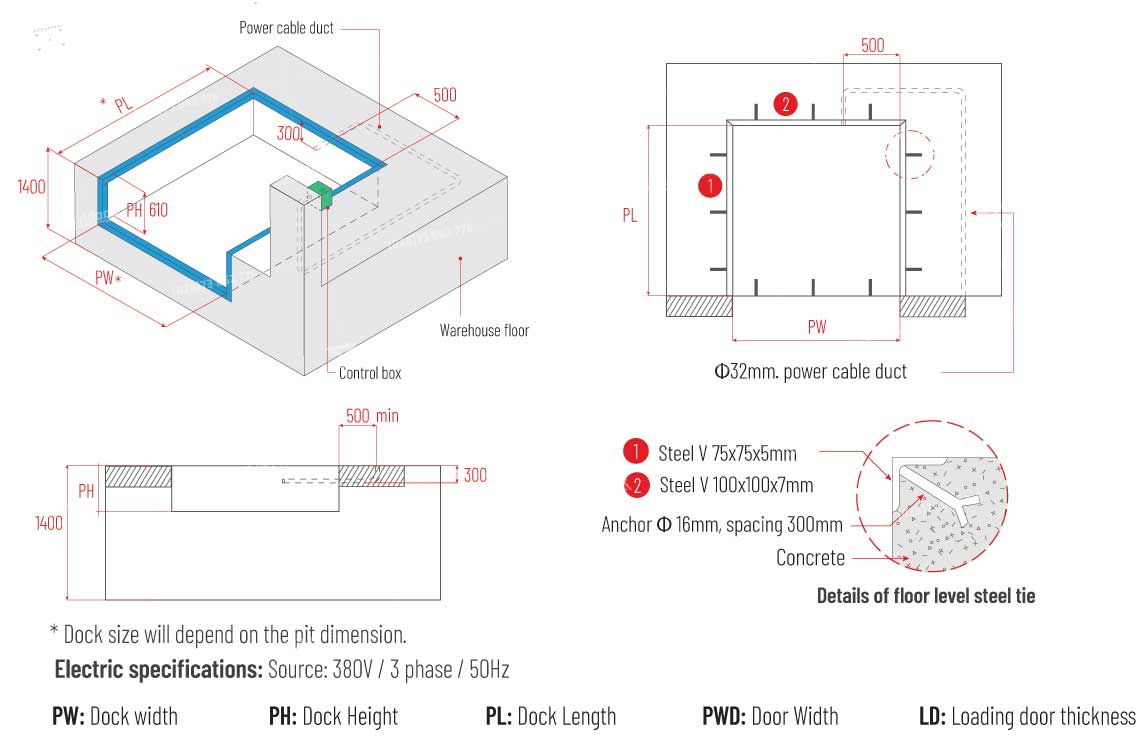

Dock Leveler, Dock Levelers, Loading Dock Leveler, Loading Dock Levelers

What is the standard loading dock height? 1.) In North America, the most commonly found dock height is 48-52 inches or (120-130 cm), though heights of up to 55 inches (140 cm) occur as well. A dock leveler can be used to bridge the gap between a truck and a warehouse to safely accommodate a forklift

Rigid Dock Shelter, Truck Dock Seals, Dock Seals

On the most basic level, designers need to make sure the loading dock leveler fits within the frame of the loading dock door (typically about 9 feet wide) as well as the trailer (commonly about 8-½ feet wide).

Design The Loading Dock Nova Technology Loading Dock Equipment

But Did You Check eBay? Check Out Dock In On eBay. Fast and Free Shipping On Many Items You Love On eBay.

Znalezione obrazy dla zapytania loading dock design dimensions Obrazy

A typical loading dock may at some point service every type of vehicle on the road. It is essential to recognize the characteristics of the trailers that will be visiting the loading dock with the highest frequency.

Loading Dock Design JustRite Equipment

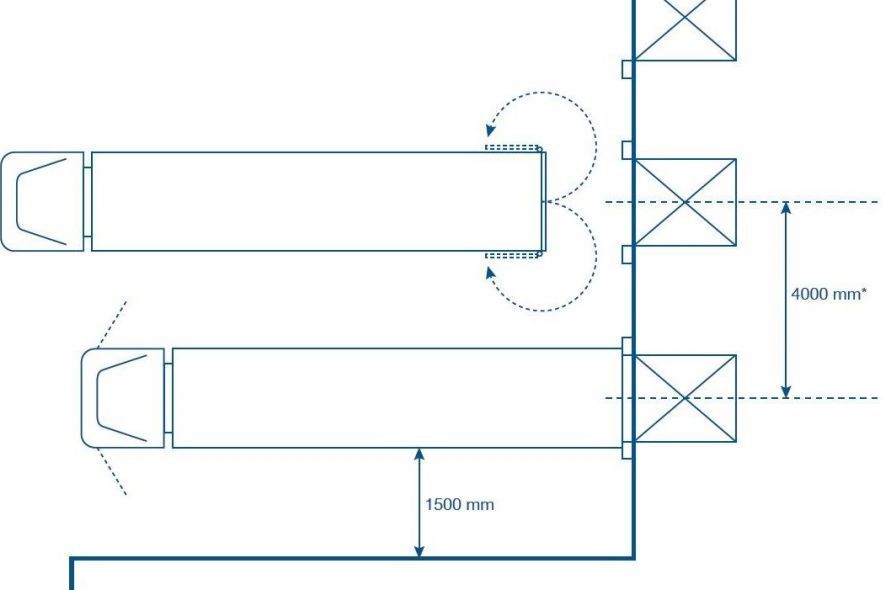

Site Design There are many types of loading dock designs, but not all are configured with efficient, logical, safe, and easy to access criteria. The loading dock is probably the busiest area of your building in terms of traffic. Forklifts, pallet jacks, and pedestrians must operate simultaneously around the dock area.

Mechanical Dock Leveler MDLND Manufacturer and Supplier NaviDock

Are you looking for a comprehensive guide to design and equip your loading dock? Download the McGuire Dock Planning Guide, a free PDF document that covers everything from dock layout, safety, lighting, doors, levelers, seals, shelters, and more. Learn how to optimize your dock efficiency and performance with McGuire, a leading manufacturer of loading dock equipment.

angled loading dock design Yahoo Image Search Results Design, Steel buildings, Floor plans

Architects who wants to learn more about loading dock design and earn CE credits, call us at (800) 624-8473 to schedule an in-person AIA-accredited training session. Otherwise click below to complete an online course. McGuire has the knowledge and resources needed for architects and design builders when planning out the design of a loading dock.

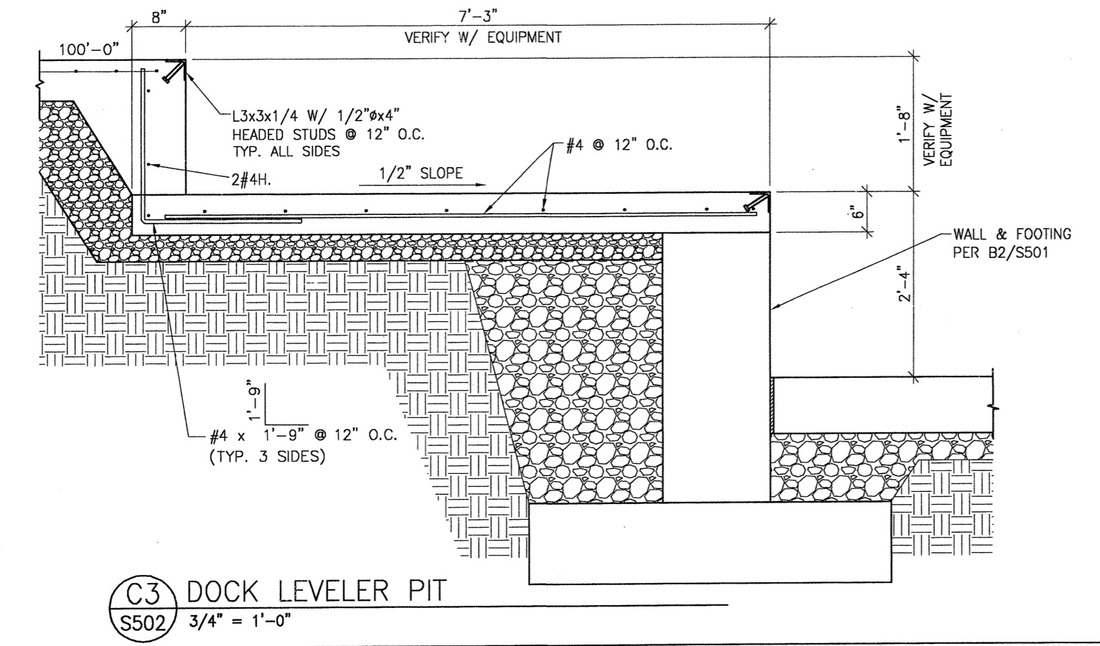

Architectural Details Architekwiki

Doors are typically 8 ft, 9 ft, or 10 ft high. 8 ft high doors can accommodate many loading and unloading operations where height is not critical, but cannot accommodate floor-to-ceiling loading (Figure1). 8 ft high doors do not maximize the usage of the available height in the trailer, which leads to higher freight costs.

Architectural Details Architekwiki

Improper size of the loading dock doors can create extra-labor for loading/unloading trucks, reducing efficiency causing product/package damage and possible employee injury.. 10" dock bumpers are the most widely used for docks where trucks come in at approximately equal heights or when only standard size trucks are received. The 12" Dock.