Calculator Bend Tooling Metal fabrication tools, Metal

Freeform Bending Tool Design for Rectangular Profiles and Its Influence on the Process Matthias Konrad Werner, Lorenzo Scandola, Daniel Maier, Wolfram Volk Author and Article Information J. Manuf. Sci. Eng. Oct 2023, 145 (10): 101009 (9 pages) Paper No: MANU-23-1075 https://doi.org/10.1115/1.4062811 Published Online: July 25, 2023 Article history

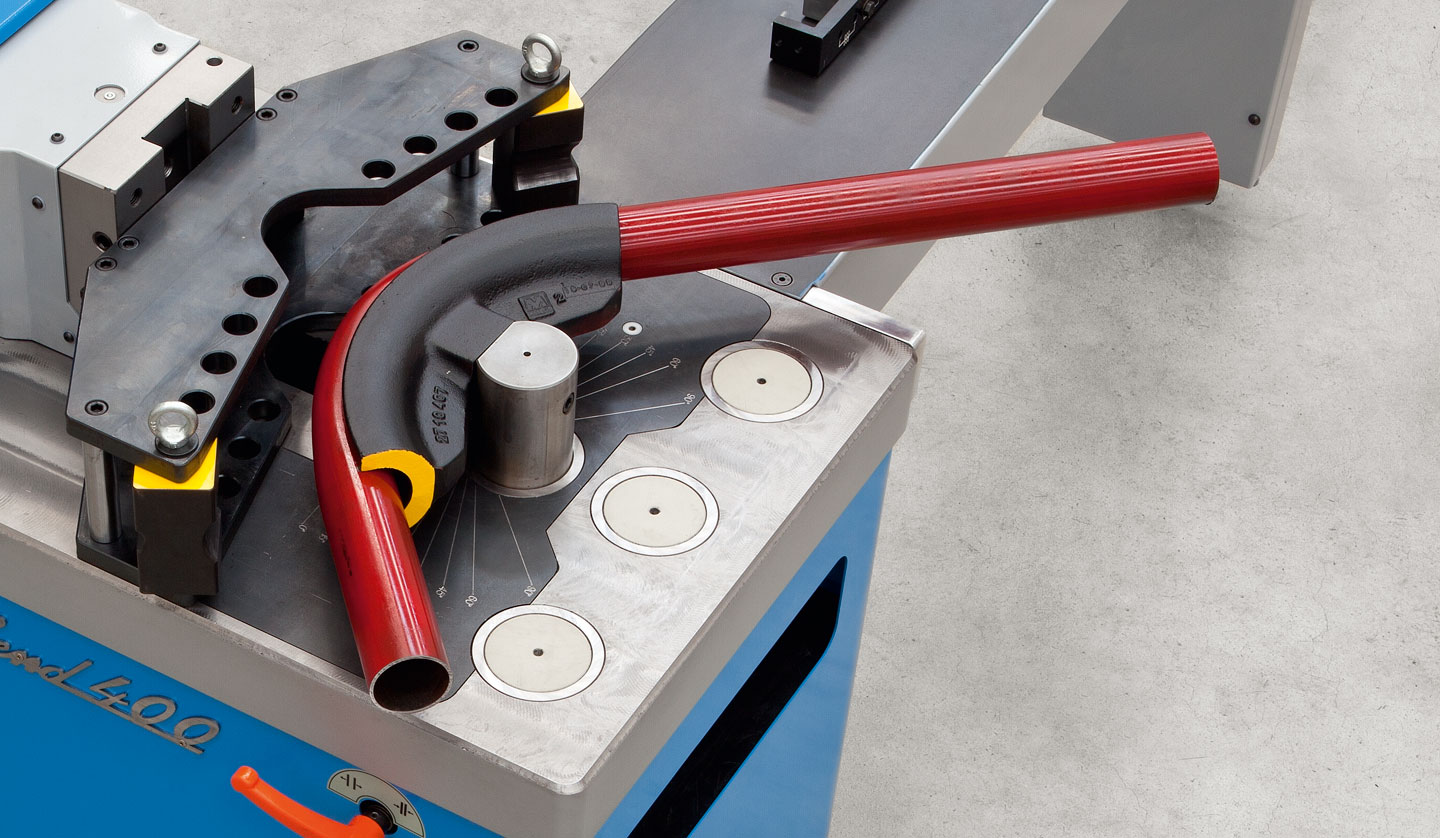

MK34 Tube bending Tool storage diy, Metal bending, Metal working

November 12, 2021 hippobender The bending of metal pipes is widely used in modern industry, mainly for automotive, machinery, boiler, chemical, shipbuilding and other industries. To ensure the quality of pipe bending processing, it is necessary to design reasonable pipe bending tooling.

DIY Scroll Bender Metal Bender For Design Bending Window Grill

1. Bend Die Hardened tool steel or alloy steel, heat treated and nitrided Clamp insert is secured with cap screws and dowel pins Drive key must be parallel to clamp insert Bore should have a slip fit over centering ring or spindle Note: Bend dies may have special tube grooves with captive lip or Empty Bending 2. Clamp Die

Make A Metal Bender Simple Homemade Powerful Metal Bender DIY YouTube

Tube Benders for Tight Spaces. Handle-free and one quarter the size of traditional tube benders, these benders fit in small, hard-to-reach spaces. Attach a 1/4" -drive ratchet wrench or extension to make bends in copper and aluminum tubing, such as brake and fuel lines— even if they're installed. Max.

Type RGC Sheet Metal Bending Machines / Folders Metal bending, Metal

Simply defined a set of tools typically refers to the (generally five piece) family of dies to bend a tube for a given outside diameter and wall thickness, to a single specified centerline radius. A fabricating company may have dozens of tooling sets each specific to the job it is designed for, and the machine designated to perform the job.

Bending tools

Nonconductive Wire Gripping and Cutting Pliers. Avoid the potential for an arc flash or short circuit that can occur when using conventional insulated tools with metal components. Completely metal- free, these pliers are plastic with ceramic cutting blades. They are tested to 1, 000 volts to meet IEC 60900 and ASTM F1505.

Bystronic special bending tools Bar bending tool YouTube

In this video you will be able to learn:- Blank Development of Bending Die - Press Tool Design- Bending Allowances- K Factor- Nuetral Axis of a bend partBend.

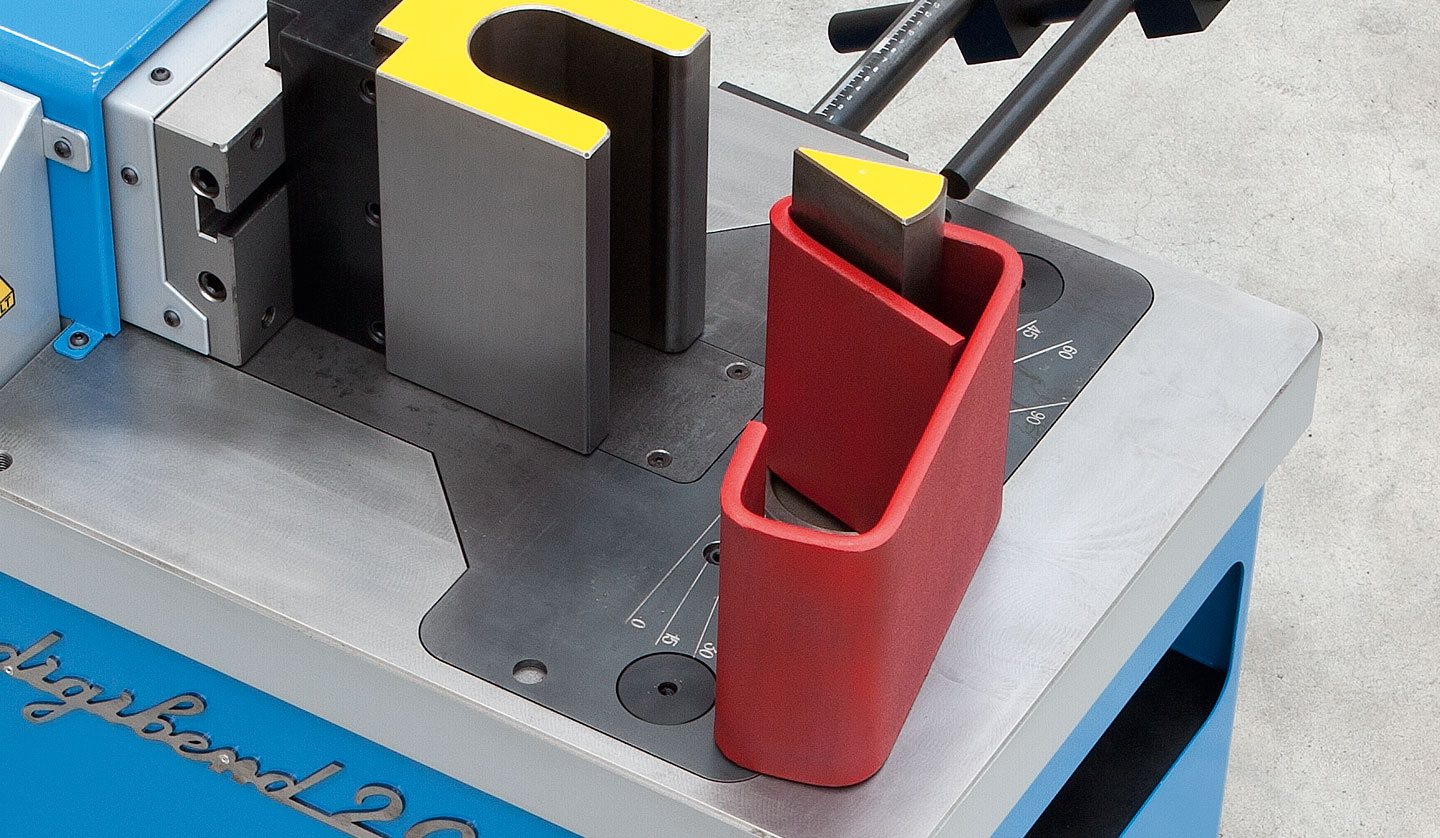

Bending machines Euromac

With the TRUMPF sensor tools for direct angle regulation in the bending process, you can successfully produce the first part in a series perfectly. Lightweight tools lessen the load of your day-to-day work. For every situation. No matter what you would like to bend - TRUMPF will develop the right tool solution for you. Quickly in hand.

.jpeg)

MicroTools Europe Tools Superior Ring Bending Tool Set by Pepetools

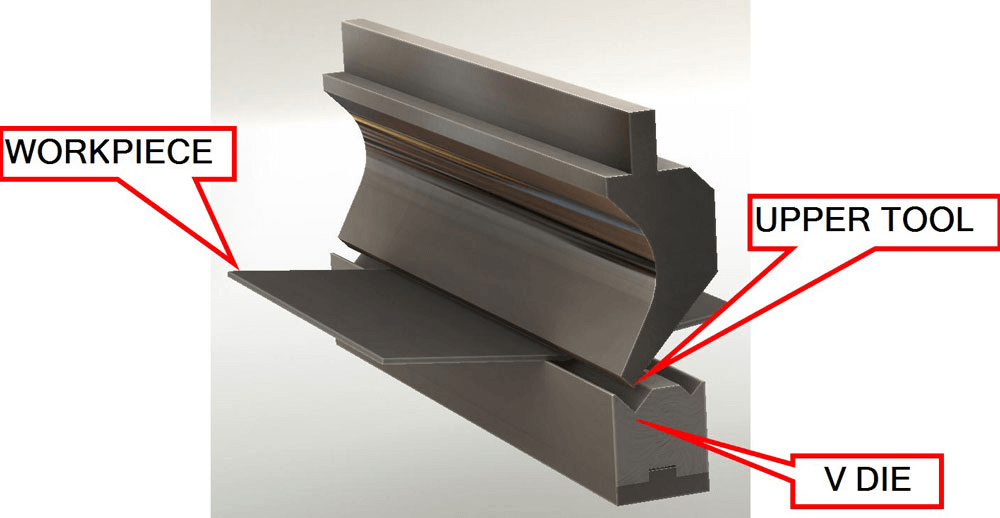

Bending is a stamping process that uses pressure to plastically deform the material, forming a specific angle and curvature shape. Common bends include V-bends, Z-bends, offset bends, and hemming bends, among others. Bending Height

Manual Bending Tool YouTube

1. Press Brake Bending Press brake or Brake Press in sheet metal parts utilizes v-types of flat punch and die to make straight sheet-metal bend at required angles. During sheet metal bending, the operator places the workpiece in a V-Die. In the die, the bending punch is pressed against the sheet metal workpiece at the bending line.

10 Best Manual Tube Bending Tool For Professionals

Also known as press braking, flanging, die bending, folding and edging, this method is used to deform a material to an angular shape. This is done through the application of force on a workpiece. The force must exceed the material's yield strength to achieve plastic deformation. Only then can you get a lasting result in the form of a bend.

The Basics of Bending Sheet Metal You Should Know

Over 35 years of expertise in bend tools, redefining "high difficulty bend tools". Competitive prices, excellent value. Top quality materials and speed on delivery. At Tools for Bending, all employees involved in the manufacture of bend tools are bending specialists, from the engineers and sales force to accounting and management.

Bystronic special bending tools U forming tool YouTube

Tools for Bending will design and manufacture high-degree-of-difficulty bending tools All Tools for Bending tooling will perform to exacting specifications. Tools for Bending quality and expertise will ensure longer tool life. Tools for Bending will provide tooling for any brand or size of bender.

Veritas Metal Bender Lee Valley Tools

Bend Tooling has a long history of innovation in both the design and manufacture of rotary draw tube bending tools. All of our products are manufactured in the only Datafacturing® licensed plant in the industry for fast delivery at low prices. The Expert Tooling Suppliers The most experienced management and engineering team in the industry.

Bending machines Euromac

The minimum distance between the knockout feature and bending edge is maintained to avoid metal deformation. (P1) Distance Between Two knockout = (5 + D) mm. To sum up, sheet metal design guidelines ensure good quality, reduced cost, and robust design sheetmetal parts. It is difficult to follow all design guidelines in the critical parts.

Bar bending tool model GR5 for bending 618 mm diameter bars, rebars

Freeform Bending Tool Design for Rectangular Profiles and Its Influence on the Process July 2023 DOI: 10.1115/1.4062811 Authors: Matthias Konrad Werner Lorenzo Scandola Technische Universität.